Labs

School of Materials Science and Engineering (NTU-MSE)

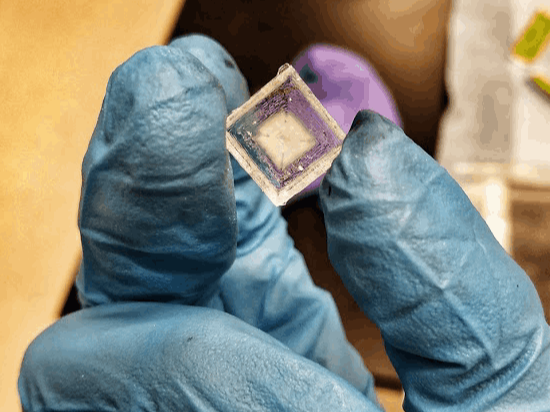

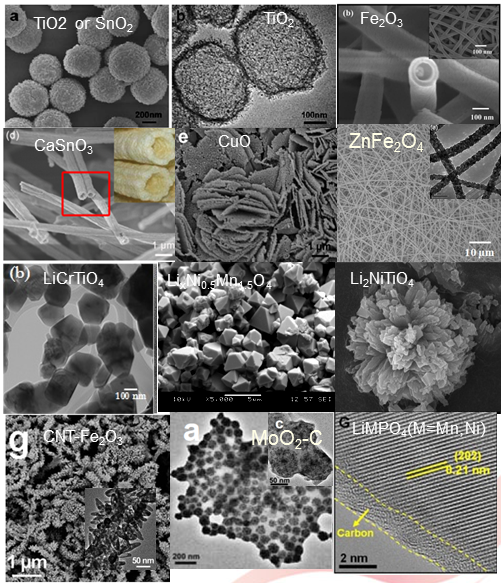

The MSE labs focus on material discovery.

click me to find out more!

click me to find out more!

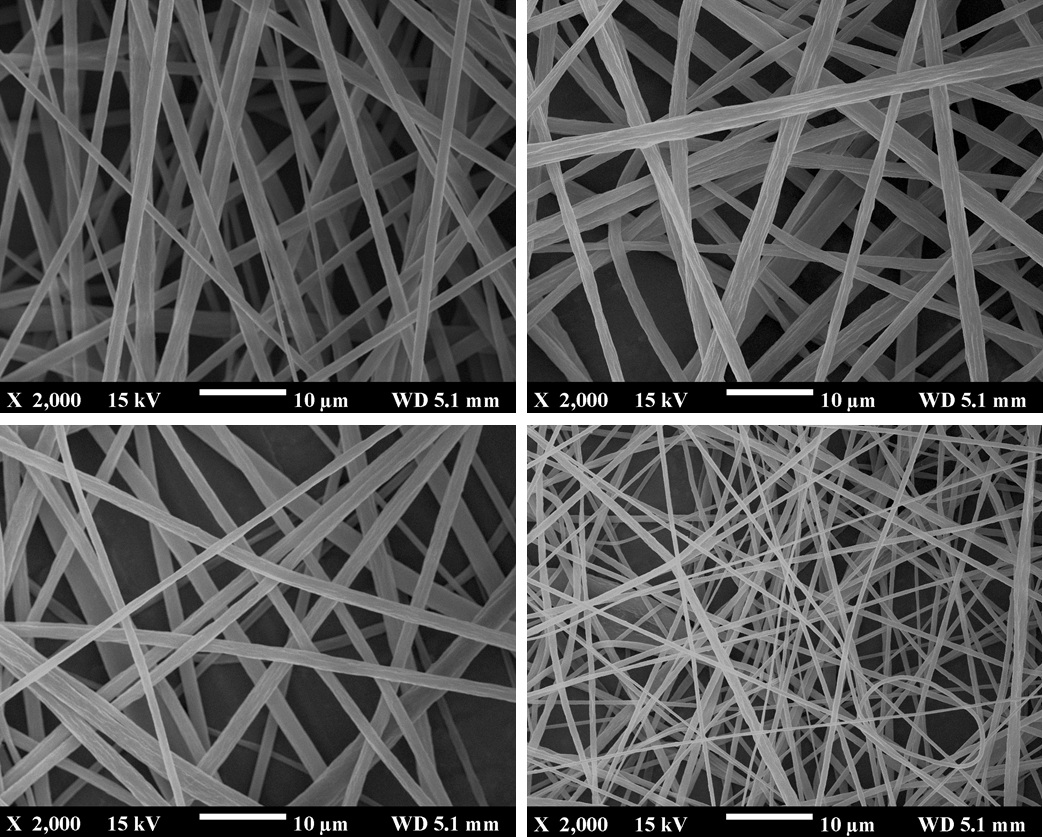

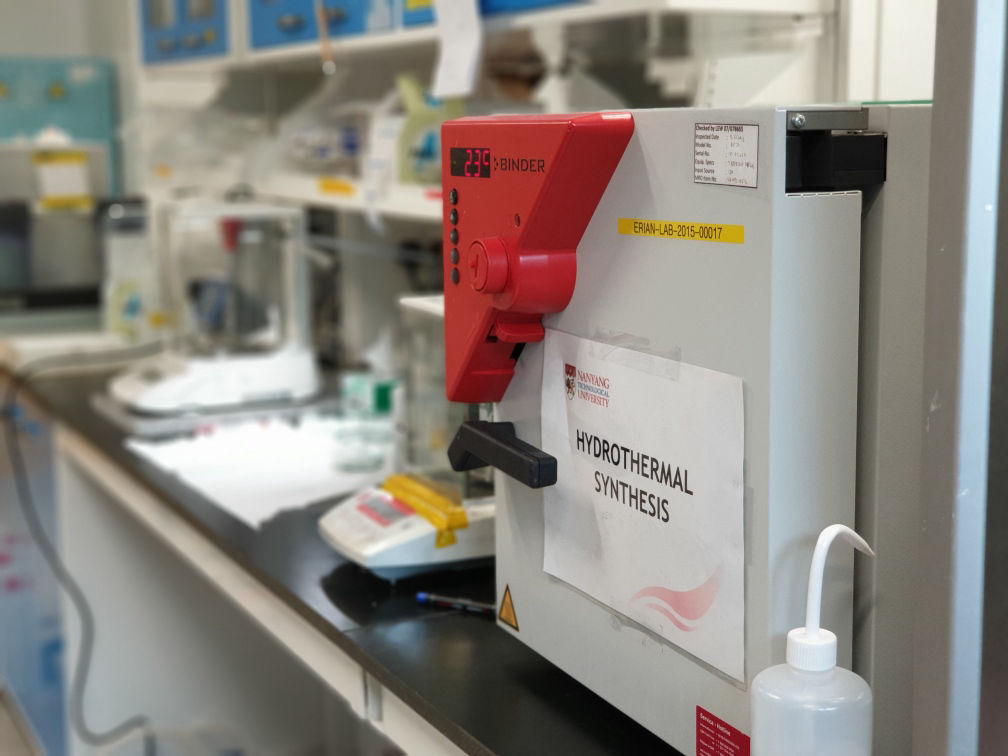

MSE reactors enable high-temperature anneals (up to 1500°C), special atmospheres, pressurized nucleation, freeze-drying, LN2 quenching, and high-energy mechanical processes. Powders, liquids, gels, castings and monoliths can then be subjected to fundamental materials characterisation (diffraction techniques / electron microscopy / spectroscopy) on site with the FACTS lab.

Lab @ SCARCE (Singapore-CEA Alliance for Research in Circular Economy)

Location: N1.2 B4-01 (map)

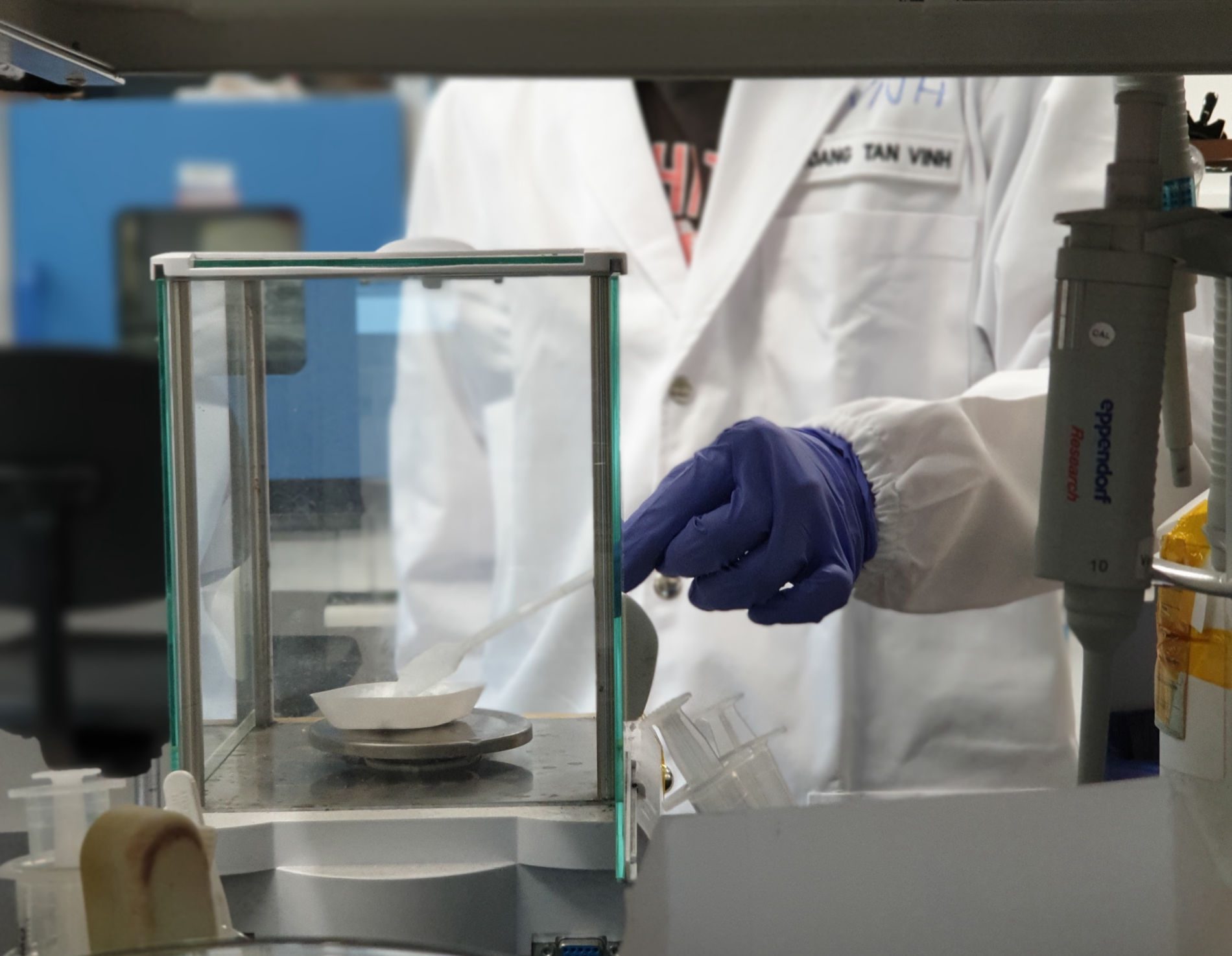

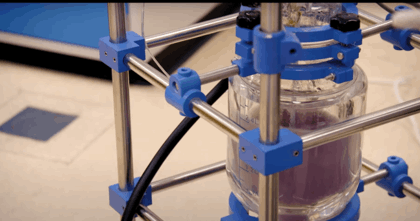

The SCARCE lab focuses on the precious resource recovery of waste electronics.

click me to find out more!

click me to find out more!

A mechanical shredder has been installed for automated grinding of modular batteries that have reached their end of life in preparation for chemical extraction processes. The feedstock can include button cells, coincells, prismatic cells and cylindrical cell packs. High-pressure reactors enable green supercritical solvent and pH-modulated extraction methodologies in a safe and efficient manner, while fitted in-line with in-situ spectroscopic monitoring. The activities here focus on transforming expired battery materials into rejuvenated batteries, to create a low-cost, environmentally-friendly, closed supply chain loop. The centre also delves into the solar cell, plastic and printed circuit board (PCB) recycling.

Prototyping Lab @ CleanTech One (CTO)

Location: CleanTech One 02-24 (map)

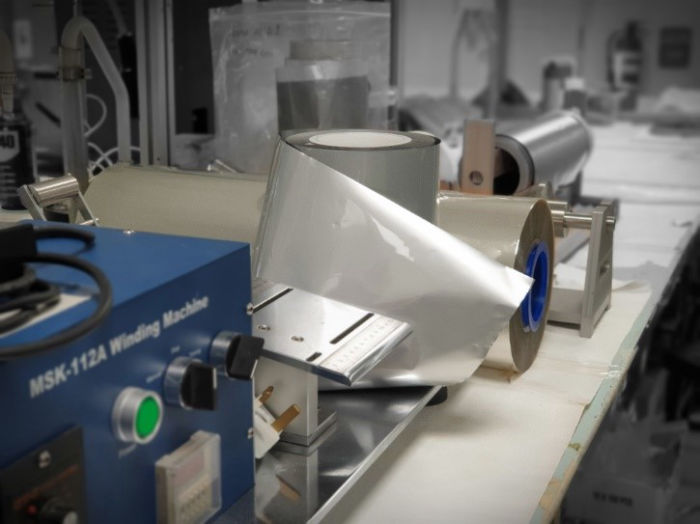

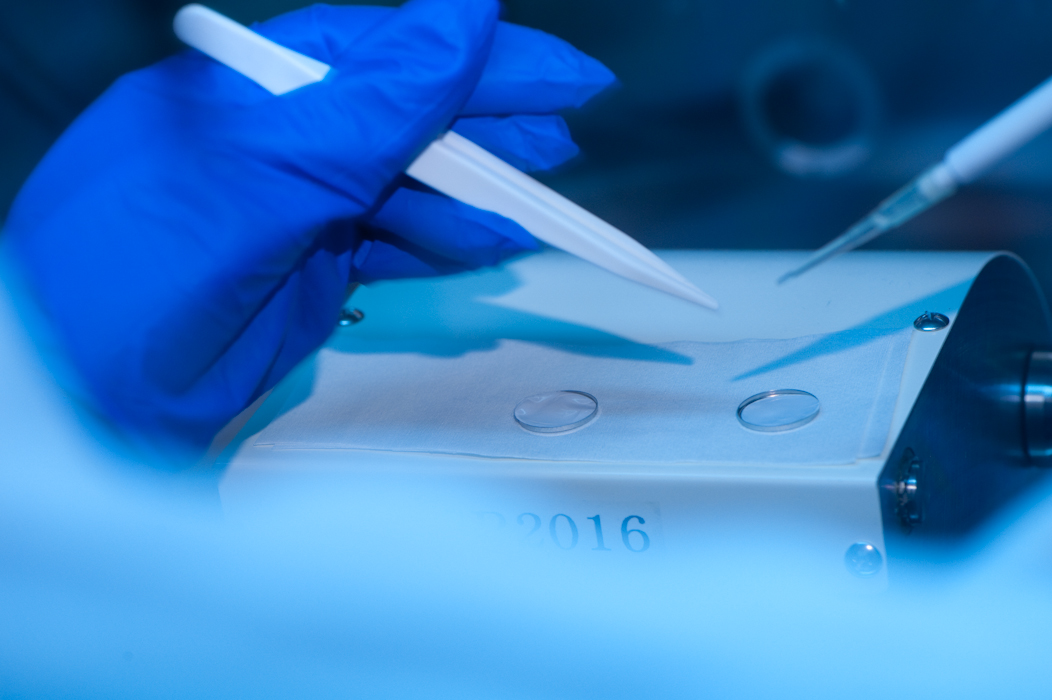

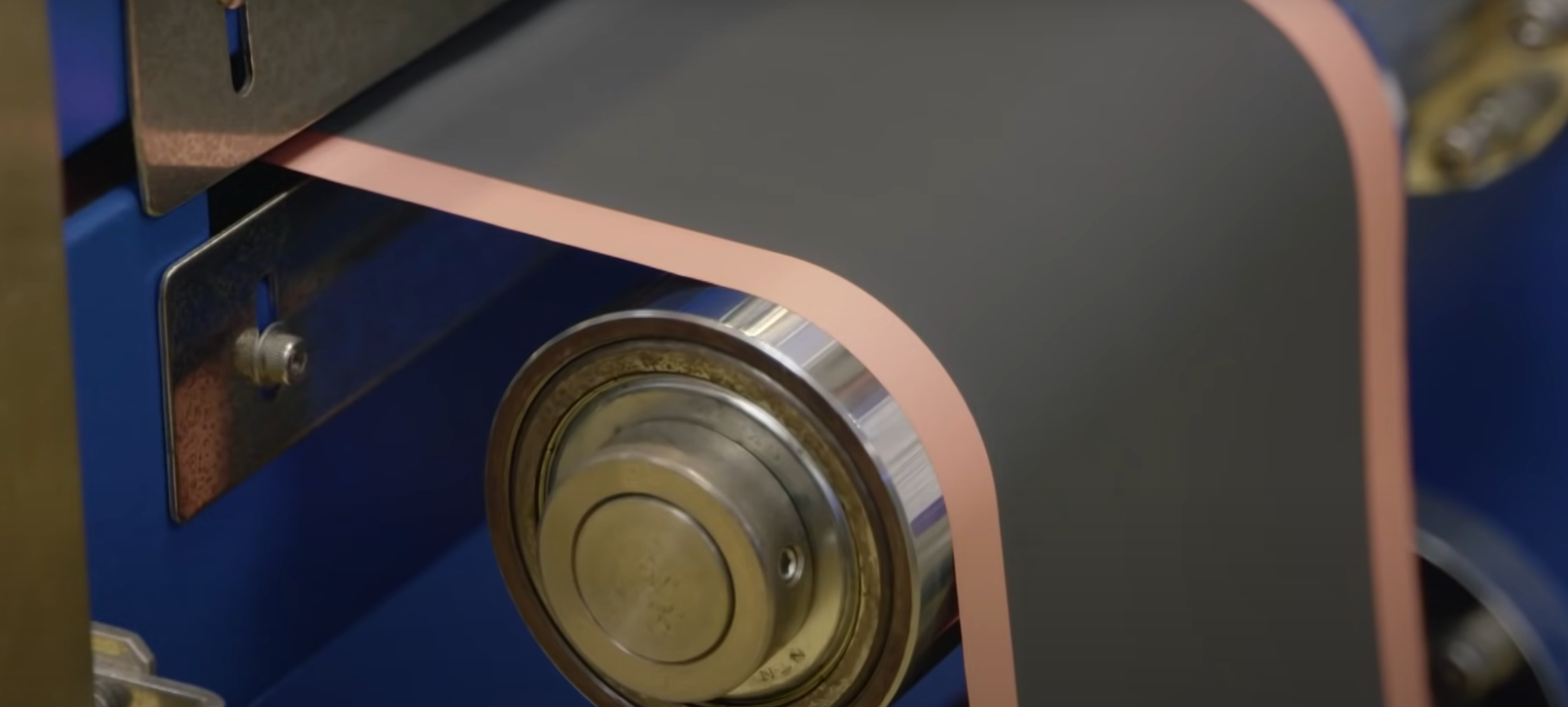

The CTO lab (ERI@N) focuses on material scale-up and testing.

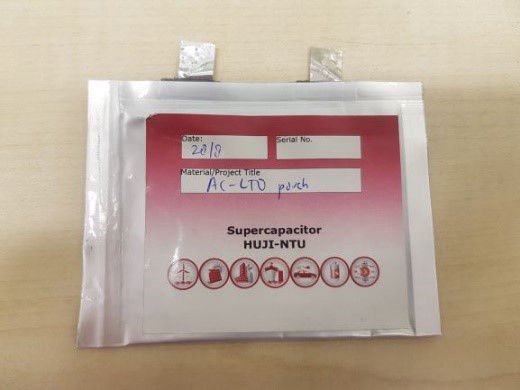

click me to find out more!

The dry-room prototyping line is equipped with all process equipment from slurry preparation, coating/pressing, cutting/tabbing, to battery/supercapacitor assembly & packaging, and electrochemical testing. This gives potential large-scale manufacturers a sneak proof-of-concept preview of the feasibility of how raw powders developed in-house can be translated to prototype pouch and cylindrical cells in Ah formats.

Key resources across labs:

• 40m2 dry-room facility, (-40ºC dew point with 2 people working inside and dehumidifying capacity of 209 g/h)

• 400+ channels battery testers

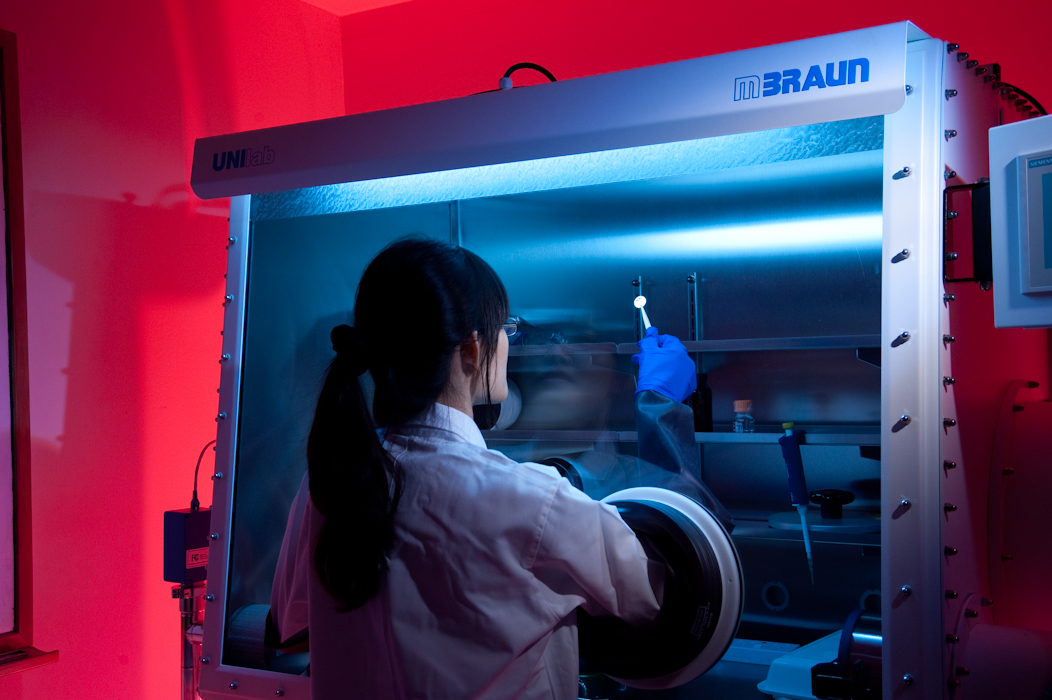

• slurry mixer, roll-to-roll coater, calendering roll press, tab welders, heat sealers, vacuum packaging, winders, Ar-filled GB

Key resources across labs:

• 40m2 dry-room facility, (-40ºC dew point with 2 people working inside and dehumidifying capacity of 209 g/h)

• 400+ channels battery testers

• slurry mixer, roll-to-roll coater, calendering roll press, tab welders, heat sealers, vacuum packaging, winders, Ar-filled GB